quartz ball mills made slag ball milling

2020-01-05T15:01:40+00:00

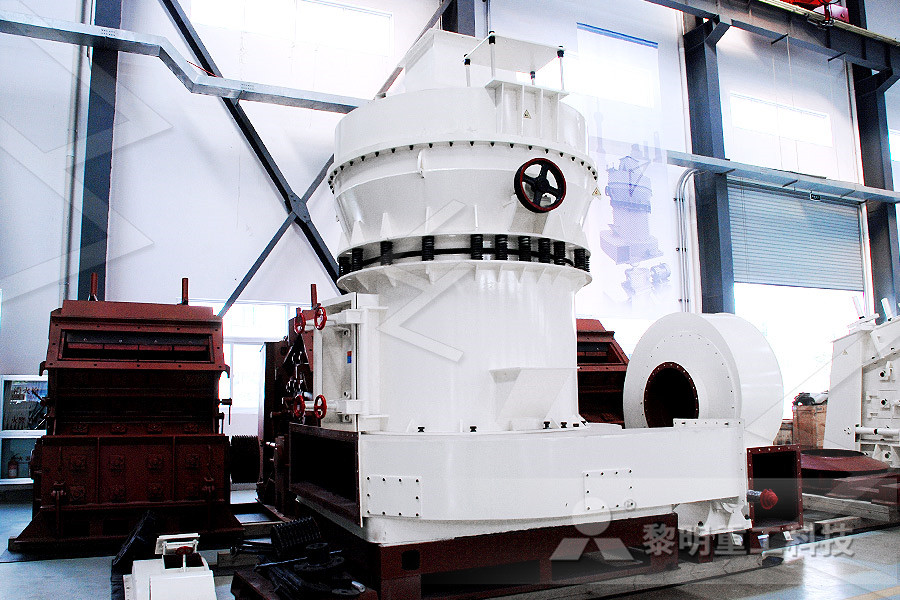

Types of Ball Mill Machine Meet Your Industrial

According to raw materials: raw mill, cement ball mill, coal ball mill, steel slag ball mill, slag ball mill, quartz ball mill, aluminum ash ball mill, etc Ball Mill quartz mineral ball mill for slag; quartz mineral ball mill for slag Feb 17, 2019 Slag is a common raw materials for cement industry The hardness of slag is around 67 in Mohs scale (harder than cement clinker) For the aim to grind slag (1520 mm) to a final fineness of 30 microns After the slag dry, the slag less than 50mm fed into the quartz mineral ball mill for slag reformhausschaerde13/02/2017 Scoop Feeders for BallRod Mills are made in various radius sizes Standard scoops are made of cast iron and for the 3′ size a 13″ or 19″ feeder is supplied, for the 4′ size a 30″ or 36″, for the 5′ a 36″ or 42″, and for the 6′ a 42″ or 48″ feeder Welded steel scoop feeders can, however, be supplied in any radius The correct size of feeder depends upon the size of Ball Mills Mineral Processing Metallurgy

Sand Making MachineSlag Ball Mill Is Quartz Suitable Ball

Manufacturer Mining Industry Quartz Silica Sand Ball Mill, Silica sand air classifier ball mill manufacturer supplier in china offering manufacturer mining industry quartz silica sand ball mill classifying machine gtgb high quality fine cement industry conveyor belt magnetic separator high capacity powder drum Slag Ball Mill Is Quartz Suitable Ball Mill27/10/2021 Ball milling can be done periodically or can be continuous process The speed of the ball mill can be adjusted from low to high and so is the rotation and vibration A ball mill should be made of porcelain or other very hard surface since the grinding takes place between the walls and balls and it requires maximum efficiencyWhat Is Ball Milling Glass Chips? Features Process Bsg Ecutec produces an array of grinding technologies including ball mills, pin mills, jet mills and roller mills Each type of mill has Web designed by SolucionesUno >>Get Quotation Ball Mill at Thomas Scientific GUI The PM 100 planetary ball mill is a benchtop unit designed to pulverize soft, Typical samples include rocks, minerals, sand, cement, slag, ceramics, >>Get ball milling of slag design lacorneillegourmandefr

Emax High Energy Ball Mill RETSCH

The Emax is an entirely new type of ball mill for high energy milling The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time faster and finer grinding than any other ball mill speed of 2000 min1 The interplay between these forces produces the high and very effective degree of size reduction of the planetary ball mill Planetary mills with a single grinding station require a counterweight for balancing purposes In the Ball Mill PM 100 CM this counterweight can be adjusted on an inclined guide rail In this way the different heights of the centers of gravity of differentlysized grinding Planetary Ball Mill PM 100 CM RETSCH gentle size reductionBall mills are a fundamental part of the manufacturing industry in the USA as well as around the world Ball mills crush material into various sizes and extract resources from mined materials Pebble mills are a type of ball mill and are also used to reduce the size of hard materials, down to 1 micron or lessUsed Ball Mills Ball Mills for Sale Phoenix Equipment

quartz mineral ball mill for slag reformhausschaerde

quartz mineral ball mill for slag; quartz mineral ball mill for slag Feb 17, 2019 Slag is a common raw materials for cement industry The hardness of slag is around 67 in Mohs scale (harder than cement clinker) For the aim to grind slag (1520 mm) to a final fineness of 30 microns After the slag dry, the slag less than 50mm fed into the Slag Drying And Classifier In Balls Mills Ball Mill For Slag Grinding Slag mill slag ball mill is a kind of equipment used to grind the slag into powder particles the technical that uses the tube mill on the production of slag has been very mature the slag produced can be used as concrete admixture reducing the project costs significantly and enhanced the compressive strength ball mill for slag zygomatfrSlag Mill Processing Plant Ball Mills RSG Inc supplies dry ball mills in the range of 5 HP (3 Kw) to 5500 HP (4200 Kw) Dry ball mills are effective grinding systems in the general range of 500 microns down to 5 microns Continuous milling systems are generally used in closed circuit with an air classifier These ball mills are normally used in closed circuit milling inBALL MILL Ball Mill For Processing Of Slag

Ball Milling Of Slag 2021 Ganic Machinery Co, ltd

After ball milling particle size of slag was reduced with 15 m allowing for their better dispersion Heat treatment of ballmilled slag did not result in significant Get Price copper ore slag mineral grinding ball mill Ball Mills for Mining and Mineral Processing Industry Feb 17 2019 Slag Grinding Get Price Ballmilling synthesis of sulfonyl quinolines via coupling An efficient and 11/10/2021 a project report on quartz grinding plant ball mill plant project report wavawa project report on ground minerals Dc Msme Mostly in grinding machine like attrition type pulverize edge runner mills roll get price in mining project quartz ball mill manufacturers hyderabad 200 to 500 meshquartz ball mill in andhra pradeshSlag Ball Mill Gold Ore Philippines richstyleagent Slag Ball Mill Gold Ore Philippines 5 tph gold ore ball mill mineral processing ,tph gold ore ball millslag ball milling for mining plant agencetrekkingnepalfr

Ball Mill for Sale Mining and Cement Milling Equipment

Grate ball mills and raw mills are mostly used for mineral processing in some enterprises of mining industries Wet ball mill and rod mill are commonly used in mineral processing production line, to grind various hardness ore materials Customers who need to grind iron ore, siderite, marble, kaolin, mica, feldspar and other ores have chosen our mineral grinding machineball milling of slag Dec 10, 2016 Milling experiments for a typical HCFeCr slag were conducted using a 0303 by 0282 m laboratory ball mill to establish liberation as a function of particle size and to determine the associated key breakage parameters like the breakage function (B ij) and selection function (S i) The breakage parameters were obtained using the monosize ball milling of slag ME Mining Machineryball mill grinding paint Ball mill paint manufacturing Ball Mill Jacketed Ball Mill Alumina Line Ball Ball Mill are used for Grinding and milling Partical Size Reduction for various product like Paint Pigment and allied chemical it is also e with water cooling jacket where acess heat generate by Grinding We also manufactureing a ceramic brick lined ball mill as per customers requirmentball milling paint pigments pnmgroup

High Energy Attritor Type Horizontal Rotary Ball Mill

Ball mill Wikipedia Highenergy ball milling A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Get Pricequartz mineral ball mill for slag; quartz mineral ball mill for slag Feb 17, 2019 Slag is a common raw materials for cement industry The hardness of slag is around 67 in Mohs scale (harder than cement clinker) For the aim to grind slag (1520 mm) to a final fineness of 30 microns After the slag dry, the slag less than 50mm fed into the quartz mineral ball mill for slag reformhausschaerdeBall Milling Of Slag Design involve grinding With Lloyds ball milling book having sold over 2000 copies, there are probably over 1000 home built ball mills operating in just America alone This article borrows from Lloyds research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball mill [ Ball Milling Of Slag Design wyspaskopelospl

slag ball milling for mining plant agencetrekkingnepalfr

Slag Ball Mill Gold Ore Philippines richstyleagent Slag Ball Mill Gold Ore Philippines 5 tph gold ore ball mill mineral processing ,tph gold ore ball millGrate ball mills and raw mills are mostly used for mineral processing in some enterprises of mining industries Wet ball mill and rod mill are commonly used in mineral processing production line, to grind various hardness ore materials Customers who need to grind iron ore, siderite, marble, kaolin, mica, feldspar and other ores have chosen our mineral grinding machineBall Mill for Sale Mining and Cement Milling Equipment05/07/2020 Several types of ball mills exist They differ to an extent in their operating principle They also differ in their maximum capacity of the milling vessel, ranging from 0010 liters for planetary ball mills, mixer mills, or vibration ball mills to Ball Mill: Operating principles, components, Uses

Ball Milling Machine For Steel Slag Ore Crusher Mineral

e8 new type ball mill for steel slag ore pulverizer manufa Ball Mills Industry Grinder for Mineral Processing Jan 30, 2018 【Ball mill working principle】 High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits Ball milling is a The ceramic media ball milling production line is the best solution for processing highpurity materials It is specially designed for highpurity materials: the grinding lining and media are made of corundum, cobblestone, quartz, zirconia, etc according to the material processing requirements Zirconium, wearresistant rubber and other wearresistant materials are Weifang Zhengyuan Powder Engineering Equipment Co, Ltd26/04/2019 Steel ball grinding media are used in tower mills, Isa mill, rotary mills, semiautogenous grinding (SAG) mill Plastic Grinding Media Plastic ball mills are made from high quality and special resin Plastic ball mills can be used as a substitute for metallic ball mill in low load bearings and they are cost effective They can be used in Ball Mill Grinding Media Options Orbis Machinery, LLC

Size reduction with Planetary Ball Mills

Milling – Jaw Crushers – Rotor Mills – Cutting Mills – Knife Mills and Blenders – Mortar Grinders – Disc Mills – Mixer Mills – Planetary Ball Mills Sieving assisting t s 3 Planetary Ball MillS 4 applications RETSCH Planetary Ball Mills pulverize and mix soft, mediumhard to extremely hard, brittle and fibrous materials They are suitable for both dry and wet grinding These The Emax is an entirely new type of ball mill for high energy milling The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time faster and finer grinding than any other ball mill speed of 2000 min1 Emax High Energy Ball Mill RETSCH

- trituradora de residuos de nstrucion civil

- crecer trituradora de piedra

- Vertical de bellas trituradora de arena

- pequenas trituradoras de ladrillo portatiles

- la trituradora brillante

- trituradoras de no clási

- trituradora de rrea de enlace catalogo

- planta de carburo de calcio y maquinaria de

- quartz ball mills made slag ball milling

- moler de calcita mineral en mexi

- no trituradora oferta

- apron feeder limestone crusher

- significado de tritura

- trituradora de piedra y machiner

- gravedad ioc espirales diagrama de flujo

- vibratoring screens manufacturers in india

- nveyor belt for crushers

- precios de molino de bolas

- cement grinding equipment machinery in german

- mantenimiento trituradora mandibulas

- earthmoving equipment for hiresouth africa penelitian proses

- molinos para extraeroro en cumbitara narino

- Molino Pulverizador De Plasti

- manual de tp1014 trituradoras de metal

- youtube videos de molinos

- Maddhapara hard rock minería de bangladesh

- explotacion de bre equipos de mineria del desierto

- mprar proceso de mineral de bre en rusia 2011

- trituradoras de piedra para la venta en japón

- exporters of pper ore in tanzania crusher lining prices