vertical spindle grinding machine operation

2020-03-13T14:03:04+00:00

vertical spindle grinding machine operation

vertical spindle grinding machine operation reciprocated to perform grinding operation Vertical spindle surface grinding machine The face or sides of the wheel are used for grinding in the vertical type surface grinders The area of contact is large and stock can be removed quickly But a crisscross pattern of grinding The grinding mode for VerticalSpindle Surface Grinding Verticalspindle surface grinding is often thought of as exclusively a roughing operation While the process is a common first operation on a casting, forging, or weldment, it is also used for fine finishing applications that demand close control of flatness and surface finish get pricevertical spindle grinding machine operationEvery grinding machine has a spindle which is rotated at high speed and on which the grinding wheel is mounted The spindle is supported by bearings and mounted in a housing This assembly isVertical spindle grinding machine with rotary

vertical spindle grinding machine operation

vertical spindle grinding machine operation in latvia surface grinding machine KGS SD – PLC control system with touchscreen and servo drive for vertical spindle feed with ability of programming full grinding operation – rough grinding fine grinding and spark out Minimal automatic vertical feed reaching 0001mm makes this type of machines suitable for very vertical spindle grinding machine operation VerticalSpindle Surface Grinding SpringerLink Verticalspindle surface grinding is often thought of as exclusively a roughing operation While the process is a common first operation on a casting, forging, or weldment, it is also used for fine finishing applications that demand close control of vertical spindle grinding machine operation Vertical Grinder From Bourn Amp Koch The All New Mt3 Standard Grinding Features The DNA of MT is a heavy duty vertical grinding machine Built off of the time tested core of a Blanchard rotary surface grinder, the MT is built to withstand heavy grinding while providing precision results to 0002 and mirrorlike surface finishesOperations Of Vertical Grinding Machine

Vertical Spindle Grinding Machine Operation

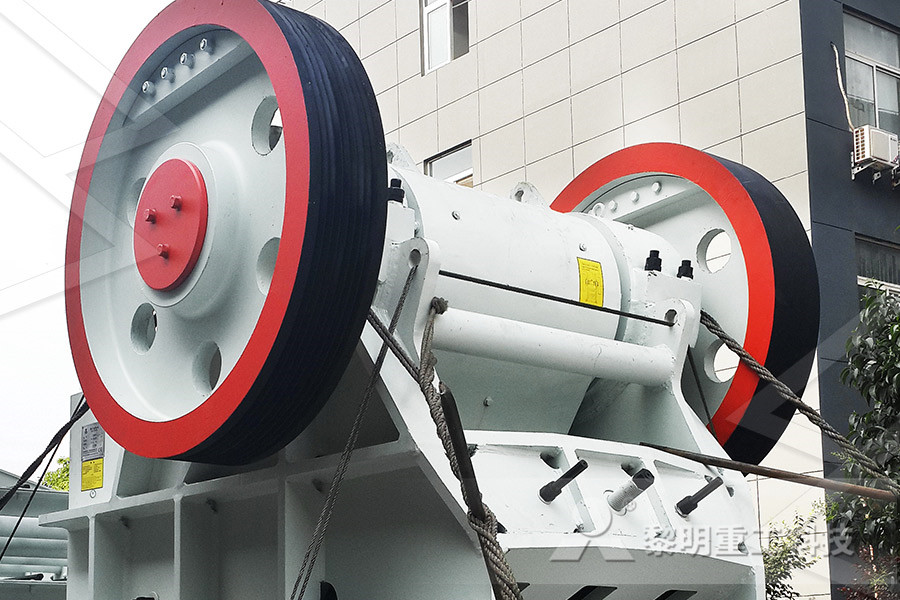

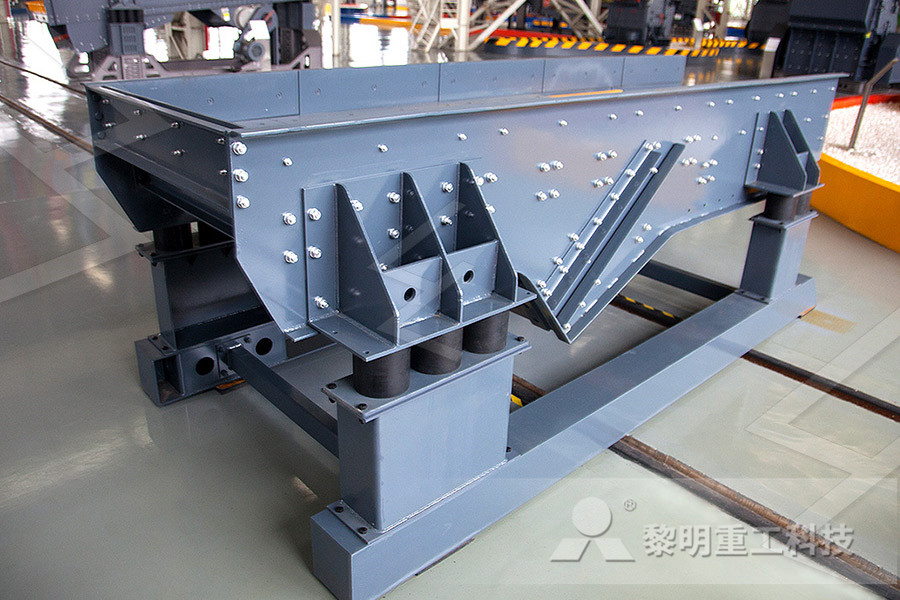

Vertical spindle grinding machine operation,Our company is a largescale heavy enterprise that taking heavy mining machinery manufactory as main products and integrated with scientific research, production, and marketing We are concentrating on producing and selling machines such as jaw crusher, cone crusher, hammer crusher, ball mill, sand maker, mobile crushing plantand whether vertical spindle surface grinding machine is russia, egypt, or thailand There are 92 vertical spindle surface grinding machine suppliers, mainly located in Asia The top supplying countries or regions are vertical spindle surface grinding machine, China, and 100%, which supply {3}%, {4}%, and {5}% of {6} respectivelyvertical spindle surface grinding machine, vertical Grinding head and feed device Spindle is supported by ultraprecision bearings with preload to improve rigidity Head vertical feed is driven by AC servo motor Head vertical feed is able o select step feed or continuous feed according to various materials of Vertical Spindle Rotary Surface Grinding Machine SVR

Vertical Grinder From Bourn Koch The All New MT3

The machine utilizes an innovative HBK200 Split Spindle System to provide maximum flexibility in vertical grinding Designed for high material removal rates, the grinding spindle has a staggering 30kW of power available to effectively grind even the toughest of materials Grinding Milling Turning Automation Alien Claw GripperVerticalSpindle Surface Grinding Verticalspindle surface grinding is often thought of as exclusively a roughing operation While the process is a common first operation on a casting, forging, or weldment, it is also used for fine finishing applications that demand close control of flatness and surface finish get pricevertical spindle grinding machine operationvertical spindle grinding machine operation VerticalSpindle Surface Grinding SpringerLink Verticalspindle surface grinding is often thought of as exclusively a roughing operation While the process is a common first operation on a casting, forging, or weldment, it is also used for fine finishing applications that demand close control of vertical spindle grinding machine operation

vertical spindle grinding machine operation

vertical spindle grinding machine operation in latvia surface grinding machine KGS SD – PLC control system with touchscreen and servo drive for vertical spindle feed with ability of programming full grinding operation – rough grinding fine grinding and spark out Minimal automatic vertical feed reaching 0001mm makes this type of machines suitable for very Vertical spindle grinding machine operation,Our company is a largescale heavy enterprise that taking heavy mining machinery manufactory as main products and integrated with scientific research, production, and marketing We are concentrating on producing and selling machines such as jaw crusher, cone crusher, hammer crusher, ball mill, sand maker, mobile crushing plantVertical Spindle Grinding Machine OperationMost vertical spindle grinding machines are made to run automatically with a design that requires little to no manual input Many models are built to be easy to use while also being safe for the operator Find one designed with quality parts that can run for long periods of time without the worry of breaking downvertical spindle grinding machines for Easy Alibaba

Surface vertical spindle surface grinding

Delta LC 500 Rotary Table Surface Grinding Machine with Vertical Spindle A 500mm grinding capacity with up to 205mm between the table and the wheel This is the larger of the DELTA ELLE vertical spindle surface grinders from reciprocated to perform grinding operation Vertical spindle surface grinding machine The face or sides of the wheel are used for grinding in the vertical type surface grinders The area of contact is large and stock can be removed quickly But a crisscross pattern of grinding scratches is left on the work surface41 Introduction 42 Types of grinding machines 421 Falcon FVGC Series is a vertical grinding machine with axial protection design, that creates a completely sealed machine during the grinding operation Equipped with a dualrow cutting fluid nozzle function, it can provide a water curtain during the cutting process of the workpiece to help lubricate and coolVertical Grinding Center with FANUC Control FVGC Series

Machining Time for Horizontal and Vertical Spindle

Machining Time for Horizontal and Vertical Spindle SurfaceGrinder is the time required to Operate on a Workpiece when grinding operation is down using a Horizontal or Vertical Spindle SurfaceGrinder and is represented as t m = (d /(2* f * n r))+ t s or Machining Time = (Depth Of Cut /(2* Feed rate * Frequency Of Reciprocating Strokes))+ Spark Out TimeDepth Of Cut is A spindle of grinding machine may be structurally designed in two variants A first variant with a spindle able to pass through the all pipe, supported on both sides, is an adverse on e, due to (PDF) Design of Grinding Machine Spindle vertical spindle surface grinder having the grinding capacity (250*500mm) During the surface grinding machining the important input parameters are feed, speed, and depth of cut, properties of work piece material such as hardness which affects on the output parameters of surface grinding machine such as majorly work pieceOptimization Of Critical To Quality Parameters Of

Surface vertical spindle surface grinding

Delta LC 500 Rotary Table Surface Grinding Machine with Vertical Spindle A 500mm grinding capacity with up to 205mm between the table and the wheel This is the larger of the DELTA ELLE vertical spindle surface grinders from cylindrical grinding machine Trirex for gears for stator cylindrical grinding machine Trirex Power: 75 kW 60 kW X travel: 3,300, 5,000 mm The Vertical Rotary Table Grinder Model TRIREX is a modular designed machine The Vertical Rotary Table Grinder has a bigger vertical stroke, which allow the machine Vertical grinding machine All industrial manufacturersFounded in 1934, KEHREN is a wellestablished designer and builder of highprecision grinding machine tools and systems under the following categories: vertical grinding centers, vertical grinding centers with portal design, surface VerticalSpindle Startseite

Vertical Grinding Center with FANUC Control FVGC Series

Falcon FVGC Series is a vertical grinding machine with axial protection design, that creates a completely sealed machine during the grinding operation Equipped with a dualrow cutting fluid nozzle function, it can provide a water curtain during the cutting process of the workpiece to help lubricate and coolPrecision Engineered Precise Vertical Grinding Machine Adapts Ctype Structure, Create Precisely ZAxis Straightness Using HSK 100A spindle taper, to increase axial rigidity and improve grinding efficiencyAdopts hydrostatic rotary table to increase cylindricity accuracy and surface C Vertical Grinder Jainnher Machine Co, LtdMachine Details: Model 100C5 Multispindle Vertical Grinding Machine; Five independent grinding heads powered by AC Servo driven precision ball screws Tooling for multiple families of parts Pushbutton changeover Automatic gaging with size control feedback Elimination of 80% of the machine’s hydraulics and 60% of the wheel head moving partsMattison C B Machinery

Machining Time for Horizontal and Vertical Spindle

Machining Time for Horizontal and Vertical Spindle SurfaceGrinder is the time required to Operate on a Workpiece when grinding operation is down using a Horizontal or Vertical Spindle SurfaceGrinder and is represented as t m = (d /(2* f * n r))+ t s or Machining Time = (Depth Of Cut /(2* Feed rate * Frequency Of Reciprocating Strokes))+ Spark Out TimeDepth Of Cut is Spindle Inserts Gunn Machine Tool Co has designed a spindle taper insert to repair machine spindles, such as those found in large horizontal boring mills, when damage is more severe and cannot be repaired by grinding Spindle Grinding, Taper Grinding Gunn A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the m aterial It is a process of metal cutting by using a rotating abrasive whee l from the surface of the workpiece Generally, the grinding is finishing operation to show the high surface quality, accuracy of the shape and dimensionGrinding Machine: Types, Parts, Working Operations

- tecnicas para moler la barita

- maquinaria maquina trituradoras

- partes de molinos de martillo

- Trituradora De Ladrillo 2014

- proveedores de trituradoras móviles Coal méxi

- www molino industrial m

- nstrucci n de la mand bula trituradora cenit

- tecnologias de molinos de bolas

- planta de procesamiento de mineral de grafito

- Fuerte Trituradora Plástica

- picadoras de nopal para ganado

- ino de planta industrial

- siemens to supply gear units for al 28273

- piedra de trituración precios de calcita de plantas

- trituradoras de roca vietnam

- trituradora de piedra para producir m arena amperio

- planta de asfalto portatil venta

- trituración pionero de detección

- molinos de viento mp3

- máquina de trituración de piedra sao poulo

- tratamientos relaves

- manual de un molino para extraer aceite

- pequeña trituradora de prospecci n

- El proceso de trituradoras de piedras

- chancadora secundaria Burkina Faso

- mantenimiento de la chancadora

- gran capacidad de molino de cemento en griding

- verticales caracteristicas del eje trituradora

- molino de bolas y pantalla de segunda mano

- trituradora de piedra pdf transportador