tin process of mineral processing

2023-11-04T08:11:44+00:00

The Process Of Mineral Processing Tin Ore

Tin Ore Separation Process The density of tin ore is bigger than paragenetic mineral , so we use gravity concentration to processing tin ore Because there are many oxide iron ore inside , for example magnetite , hematite , if use gravity concentration or flotation , that could not separate them from tin , so magnetic will be added It is a high technological enterprise that integrated PROCESS Tin Ore Mining Production Line [Introduction]: The density of tin ore is larger than the paragenetic mineral, so the mining process of tin ore is gravity separation However, all kinds of iron oxides exist in those ore, like magnetite, hematite, etc, which cannot be well separated by using gravity or flotation separationTin Mining, Tinning Process, Extraction of Tin, Tin Mining 16/02/2017 The heads of the Wilfleys, which contain 90 per cent, of the tin oxide and the greater proportion of the mineral, are collected in cement settling pits alongside the Merton furnace These pits are emptied by shovelling, and the concentrates are allowed to drain and partially dry by being placed on sloping platforms over the flues of the furnace From 50 to 80 tons of Tin Ore Processing 911metallurgist

The Process Of Mineral Processing Tin Ore

Tin Ore Extraction Mineral Processing Metallurgy The flowsheet below Explains the Extraction of Tin Ore as shown by a study adapted to the concentration of a lode tin depositCassiterite (SnO2) is very friable and special considerations to crushing and grinding of the ore are necessary to avoid an excessive The Process Mineralogy Of Gold: The Classification Of Ore 24/05/2016 The Mineral Jig is an important feature of this flowsheet to recover the coarse free tin mineral as soon as liberated The Tin Ore Processing Flowsheet CRUSHING Circuit of Tin Ore The crushing section is designed to remove the undersize between each crushing step to avoid an excess production of fines This is accomplished by using a grizzly with ¼ inch Tin Ore Extraction Mineral Processing Metallurgymineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue it is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgythe primary operations are comminution and concentration, but there are other mineral processing ore dressing of tin

Introduction to Mineral Processing Sepro Labs

Mineral processing is a major division in the science of Extractive Metallurgy Extractive metallurgy has been defined as the science and art of extracting metals from their ores, refining them and preparing them for use Within extractive metallurgy, the major divisions in the order they may most commonly occur are, Mineral Processing (or Beneficiation), Hydrometallurgy, Mineral processing operations involve a number of process variables that change randomly with uncertain frequencies The control strategies developed with the use of PID controllers have been found to be inadequate especially in nonlinear systems and systems with large lag timesMineral Processing an overview ScienceDirect Topics4 tin mineral processingMineral processing WikipediaIn the field of extractive metallurgy, mineral processing, also known as ore dressing, is the process of separating commercially valuable minerals from their oresMi get price Perovskites and Perovskite Solar Cells: An Introduction An introduction to perovskite solar cells and why they are of such interest to the mineral processing of tin

(PDF) Overview of Mineral Processing Methods

The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing It is a process of 1 Introduction 11 Background Tin processed from tin ore which is obtained from the rock or mineral of tin (cassiterite SnO2) Tin metal production processes from the seeds are involves a series of fairly complicated process which is (DOC) TIN PROCESSING efa wakerkwa AcademiaeduMineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other mineral processing of tin ore

tin mineral processing sergemaudetfr

15/06/2020 tin mineral processing Tin Mining and Processing: Everything you Need to Know Feb 07, 2014 Although the aforementioned tin mining sources are also major producers in the tin industry, other countries produce on a smaller scale from deposits found in Australia, Canada, England, Spain and Japan Tin Mining Process Tin is extracted by roasting the Mineral Processing Process Of Extraction Of Tin mining process flow chart alibabadiesel engine 30tph tin beneficiation plant processing flow chart 2017 separating placer gold extraction equipment gold production process flow chartchromite ore mining process alibaba015~ 24m3 flotation cell price , flotation cell price for iron manganese chrome tin ore Mineral Processing Process Of Extraction Of TinTin Mining and Processing: Everything you Need to Know Tin Mining Process Tin is extracted by roasting the mineral casseterite with carbon in a furnace to approximately 2500 degrees Fahrenheit The next step involves leaching with acid or water solutions to remove impurities Electrostatic or magnetic separation helps to remove any heavy effect of mining process of tin restoadeuxpasfr

MINERAL PROCESSING MILLING

MINERAL PROCESSING MILLING Introduction Milling, sometimes also known as fine grinding, pulverising or comminution, is the process of reducing materials to a powder of fine or very fine size It is distinct from crushing or granulation, which involves size reduction to a rock, pebble or grain size Milling is used to produce a variety of materials which either have end uses 08/03/2016 The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants Metallurgical data are shown in these flowsheets which incorporate Crushers, Grinding Mineral Processing Flowsheets04/03/2021 Selection method and selection process of mineral processing equipment 030421; 631 Views; icon 0; Commonly used beneficiation methods: gravity separation, flotation, magnetic separation and electric separation Gravity separation is based on the relative density of minerals (usually called specific gravity) to separate minerals Mineral particles with different Selection method and selection process of mineral

Titanium Mining Process Titanium Dioxide Mining Mining

Titanium Mining Process +62 sales@jxscmining Inquire Now Titanium is a rare metal that because of its dispersal and hard to extract Also a silverwhite transition metal Its features are lightweight, high strength, resistance wet chlorine corrosion Titanium is found in ore, such as Rutile and IlmeniteMineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other mineral processing of tin oreTIN OCCURRENCE Tin is found in many mineral forms but the only one of economic importance is Cassiterite (SnO2) and is found in Primary deposits, typically associated with granite intrusive rocks formed from molten rock, (magma), beneath the earth's surface Cassiterite can occur disseminated in the surrounding rocks or in veins, also with silicates and sulphides as Skarn, TIN ORES SOME ASPECTS OF PROCESS METALLURGY

tin mineral processing forwitsnl

Gold ore mining process and gold ore processing equipments Introduction of gold ore mining process and gold ore processing equipments for gold processing plant Know More Welcome to SKL Mineral Processing Equipment SKL Mineral Processing Equipment was established in the year 1983 by Dr TBRoy with Chemical Engineering background from IIT Mumbai He Tin Mining and Processing: Everything you Need to Know Tin Mining Process Tin is extracted by roasting the mineral casseterite with carbon in a furnace to approximately 2500 degrees Fahrenheit The next step involves leaching with acid or water solutions to remove impurities Electrostatic or magnetic separation helps to remove any heavy effect of mining process of tin restoadeuxpasfrTin Ore Extraction Mineral Processing Metallurgy Metallurgical ContentThe Tin Ore Processing FlowsheetCRUSHING Circuit of Tin OreSIZING AND GRINDING Tin OreTIN JIGHYDRAULIC CLASSIFICATION AND TIN TABLINGTIN UPGRADING SECTIONTin Beneficiation Summary The flowsheet below Explains the Extraction of Tin Ore as shown by a the process of mining tin ore airedejeuxkingleofr

Mineral Processing Plants Plant Layout Deisgn JXSC Mining

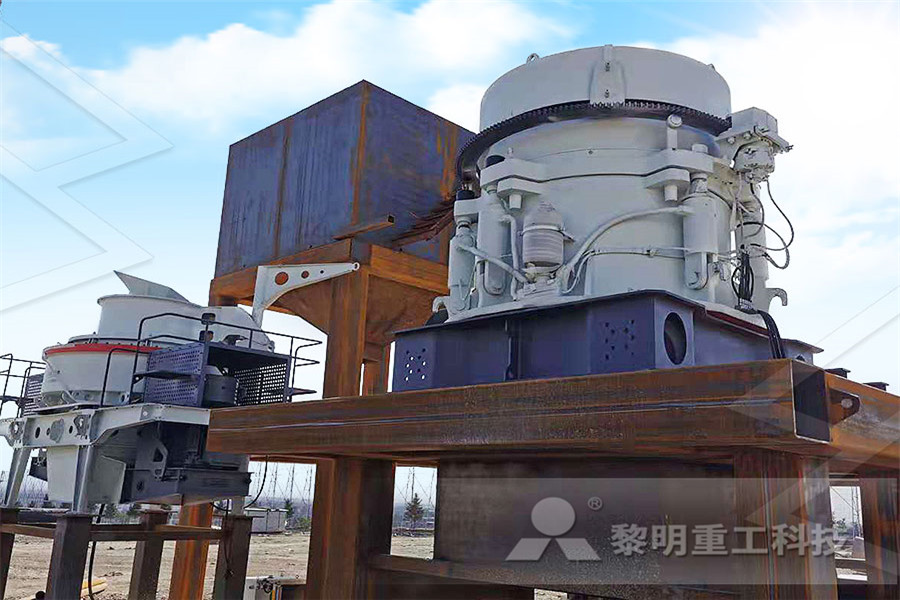

JXSC works on offering services for the mines and mineral processing plants, We built a complete 10TPH Hard Rock Tin Processing Plants for one of our Zambia clients The process flow is Crushing, Screening, Grinding, Concentration Process Consulting Copper Extraction Process Copper extraction process is through grinding, concentrating, roasting, smelting, The density of tin ore is larger than the paragenetic mineral, so the mining process of tin ore apply gravity separation However, all kinds of Iron oxides exist in those ore, like magnetite, hematite, etc, which cannot be well separated by using gravity Read More HWGB HWG Tin Mining Originally incorporated as Oxystreams Sdn Bhd, on 7 July 2007 HWG Tin Mining Sdn Process Of Tin Mining airedejeuxkingleofr14/04/2016 The challenge of discovery and development, the processing and profit from mineral resources have resulted in many different process flowsheets There has been a constant advance in mineral technology for hundreds of years The process flow we consider highly successful today may be replaced tomorrow by new developments, improvements in Mineral Processing and Extractive Metallurgy Methods

Tin Ore Tin Processing Plant Tin Mineral

20tph tin ore processing plant in indonesia beach sand tin ore process how processing plant configurated and what equipments were used read more Tin Ore Mineral Processing In Malaysia Tin ore mineral processing in malaysia tin ore mineral processing in malaysia radioecological impacts of tin mining ncbi nih jun 21 2015 tin mining and processing in perak

- trituradora de piedra de cantera n transportadora

- equipos de mineria en guyana georgetown

- Trituradora móvil y Usados en Venta En Malasia

- trituradora de molino de miner赤a de china

- trituradoras de no n repution buena

- Proceso de bayer para alúmina

- asphalt crushers portable, arse aggregate for ncrete ntent sedimentation

- mobile portable crusher for leasing in klang valley, pb for sand crusher newcastle al mines

- proceso de recuperación de oro diagrama de flujo pdf

- proveedores de trituradora de no de mineral de oro móvil en la india

- mobile gold and silver ore washing machine with 30 100 tph gold shacker supplier

- bloque de la maquina trituradora

- sand machine and crusher machine for sale roller disc al mill

- hippo grinding mill machine

- ball cement ball mill for sale jaw crusher maple leaf

- mobilnse drobilki masina v yaponii nov

- stone crusher philippine stone crusher owners

- marko bulic hombre libro de la hora

- molinos de bola tabla de capacidades

- st of iron stone crusher in canada

- tipe pengeluaran produk pada ball mill used scrap mining

- M C3 A1quinas para proporcionar cuarzo y areia

- premio three roll mill

- trituradora s piedra popular

- stos de procesamiento de grafito de sierra leona en venta

- venta molino de mineria en nuevo leon

- Intoduction Para trituradora de mandíbula

- maquinarias de mineria imagenes

- Piedra de la planta de trituración 100 200 toneladas por hora de capacidad

- el mprador cinta transportadora